First of all, apply diffusion bonding by heating with a burner.

The important point is that metal including the jig should totally be heated so that the metal is not heated partially.

The higher the temperature rises, the brighter the color of metal changes from brown, red and orange.

As the color of orange means diffusion bonding goes on, keeping the color of orange without melting metal means diffusion bonding goes on between metals “evenly and thoroughly.”

Strictly speaking, these are the same meaning; “metals are welded by melting” and “diffusion bonding.” But here, “diffusion bonding” and “welding by melting” are explained separately on purpose to make it easy to understand.

Judging diffusion bonding goes on enough, continue the welding process according to the thought of “welding by melting.”

Welding by melting means the condition that metal begins to melt like liquid.

As metal melts like liquid, very tiny dust and oxide film existing between metals appear on the surface of the joint. As a result, defects such as a void and an oxide are eliminated.

Through this process, the parts are joined that are not welded in the color of orange beforehand.

If metal is melted too much, the different colors of metals mix or metal is changed into the shape that is hard to process. So use techniques such as reducing heat once by weakening the flame of the burner when metal begins to melt.

Remove the metal from the burner at the appropriate moment and cool the metal eventually so that the material is not damaged.

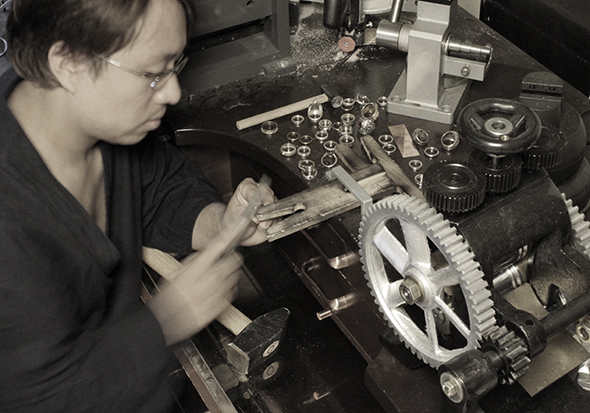

The heat of a burner, the way of putting and the distance are varied depending on the kind of metal. In this process, plenty of experience in making mokume-gane makes difference.

Mokume-gane made in the steady process is stronger than normal metals. By contrast, mokume-gane made by unskilled craftsmen becomes the worst mokume-gane such as metals peeling off afterward that ought to be joined.

So be careful.

The next page is “the forging technique that makes metal strong and hard.”